A float switch in a lubrication system is a type of level sensor used to monitor the oil or

lubricant levels in various industrial machines and equipment. It plays a crucial role in

maintaining proper lubrication levels, which is essential for the smooth and efficient operation

of machinery.

Here's how a float switch typically works in a lubrication system:

| MODEL | DESCRIPTION |

|---|---|

| MODELHLFSH | DESCRIPTIONFor motorised lub. unit, for electrically oil level sensing NC / NO contact |

| MODELHLFSH + | DESCRIPTIONFor motorised lub. unit, for electrically oil level sensing NO+NC contact |

| MODELHLFSV | DESCRIPTIONFor motorised lub. unit, for electrically oil level sensing NC / NO contact |

| MODELHLFSV + | DESCRIPTIONFor motorised lub. unit, for electrically oil level sensing NO+NC contact |

A pressure switch in a lubrication system is a device used to monitor and control the pressure

of lubricating oil or fluid within the system. It is commonly employed in machinery, engines,

and other equipment that require proper lubrication to operate effectively and prevent damage

from friction.

The pressure switch typically consists of a sensing element, which can be a diaphragm or a

piston, and electrical contacts. When the pressure of the lubrication system reaches a certain

predetermined level, the sensing element responds by activating or deactivating the electrical

contacts. This change in the status of the contacts can trigger various actions, such as turning

on or off a lubrication pump, activating an alarm, or shutting down the equipment to prevent

further operation without adequate lubrication.

| MODEL | DESCRIPTION |

|---|---|

| MODELHLPS-830 | DESCRIPTIONPressure switch used in motorised unit for Sensing pressure. |

| MODELHLPS-020 | DESCRIPTIONPressure switch used in motorised unit for Sensing pressure. |

A pressure gauge in a lubrication system is a device used to measure and display the pressure of

the lubricating oil or fluid within the system. It provides real-time information about the

pressure levels, allowing operators to monitor and maintain optimal operating

conditions.

The pressure gauge consists of a pressure-sensitive element, usually a bourdon tube or a

diaphragm, and a calibrated scale that indicates the pressure reading. As the lubrication system

operates, the pressure of the oil or fluid exerts a force on the pressure-sensitive element,

causing it to deform. This deformation is then translated into a pressure reading on the gauge's

scale.

It's important to note that pressure gauges should be selected and installed based on the

specific requirements of the lubrication system and the operating conditions. Factors such as

pressure range, accuracy, durability, and compatibility with the fluid being measured should be

considered.

| MODEL | DESCRIPTION |

|---|---|

| MODELHLPG-025 | DESCRIPTIONDial size 40 mm, Bottom connection 1/8" NPT, Pressure range 0-25 Kg/cm2. |

| MODELHLPG-028 | DESCRIPTIONDial size 50 mm, Bottom connection 1/8" NPT, Pressure range 0-28 Kg/cm2. |

| MODELHLPG035 | DESCRIPTIONDial size 63 mm, Bottom connection 1/8" NPT, Pressure range 0-35 Kg/cm2. |

An oil filler in a lubrication system is a component that allows for the convenient and

controlled addition of lubricating oil or fluid into the system. It serves as a port or opening

through which fresh oil can be added to replenish the system and maintain the proper oil

level.

The oil filler typically consists of a cap or cover that secures the opening and prevents

contaminants from entering the lubrication system. It may have a built-in vent or breather to

equalize pressure inside the system during the filling process. Some oil fillers may also

incorporate a filter or strainer to remove any particles or impurities present in the oil being

added.

When the lubrication system requires additional oil, the oil filler cap is removed, and

fresh oil is poured or pumped into the system through the opening.

| MODEL | DESCRIPTION |

|---|---|

| MODELHLB-03 | DESCRIPTIONUsed for CLU-03/ALR-03/SLU-2700 Motorised unit. |

| MODELHLB-20/30 | DESCRIPTIONUsed for CLU-05 / CLU-08 / CLU-20 Motorised unit. |

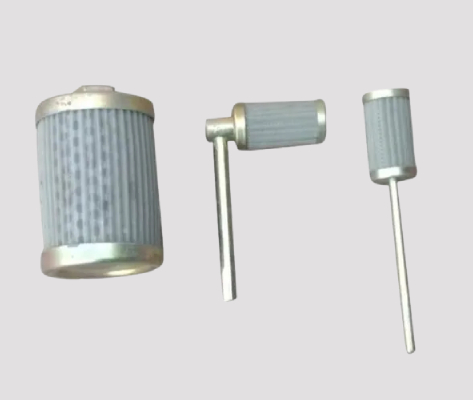

A suction strainer, also known as a suction filter or intake strainer, is a component commonly

used in lubrication systems to remove contaminants and debris from the incoming oil before it

enters the system's pump or other components. It is typically positioned at the inlet of the

pump or suction line to protect the system from potential damage caused by particulate matter in

the lubricating oil.

The primary function of a suction strainer is to prevent solid particles, such as dirt,

metal shavings, and other debris, from entering the lubrication system. These particles can

cause wear, abrasion, and clogging of components, leading to reduced system efficiency and

potential failure.

A suction strainer is typically constructed using a mesh screen or perforated metal filter

element housed in a casing.

| MODEL | DESCRIPTION |

|---|---|

| MODELHLSS-08 | DESCRIPTIONFor CLU-03 Motorised lubrication unit. |

| MODELHLSS-30 | DESCRIPTIONFor CLU-05 / CLU-08 Motorised lubrication unit. |

| MODELHLSS-50 | DESCRIPTIONFor pump PP-08 & PP-10 |

A relief valve in a lubrication system is a safety device designed to protect the system from

overpressure. It is responsible for preventing excessive pressure build-up within the system by

releasing or relieving the excess pressure when it exceeds a predetermined set point.

The relief valve consists of a valve mechanism, a spring, and an adjustable pressure setting.

The valve is normally held closed by the force of the spring, keeping the lubrication system

pressurized within a safe range. When the pressure within the system exceeds the set point, the

force exerted by the excess pressure overcomes the spring tension, causing the relief valve to

open and divert the excess fluid or oil flow.

Once the relief valve opens, the excess fluid is typically directed to a low-pressure area, a

reservoir, or back to the oil sump, depending on the system's design.

| MODEL | DESCRIPTION |

|---|---|

| MODELHLRV-030-A | DESCRIPTIONUse for pressure setting in Motorised Units. |

| MODELHLRV-030-B | DESCRIPTIONUse for pressure setting in Hyd. / Lub. Units. |