They are suitable for centralized manual lubrication of light-duty automatic machines, such as

small power presses, packing machines, milling machines, single spindle automats, looms, surface

grinders, pouch-filling machines, etc. Usually these pumps are suitable for 2-40 lubricant

points.

This is a piston pump with oil reservoir of different capacity. The pump discharges oil on

pulling the handle. The piston returns to its original position by spring force and pressure

generated approx.

| MODEL | DISCHARGE | RESERVOIR | MAX. PRESSURE |

|---|---|---|---|

| MODELHLH-7 | DISCHARGE7cc per stroke | RESERVOIRwithout | MAX. PRESSURE12kg/cm² |

| MODELHLH 250-4 | DISCHARGE4cc per stroke | RESERVOIR0.25 Ltr. | MAX. PRESSURE12kg/cm² |

| MODELHLH 600-6 | DISCHARGE6cc per stroke | RESERVOIR0.60 Ltr. | MAX. PRESSURE15kg/cm² |

| MODELHLH 2000-10 | DISCHARGE10cc per stroke | RESERVOIR2 Ltr. | MAX. PRESSURE20kg/cm² |

| MODELHLH 400-5* | DISCHARGE5cc per stroke | RESERVOIR0.40 Ltr. | MAX. PRESSURE15kg/cm² |

| MODELHLH 600-5* | DISCHARGE6cc per stroke | RESERVOIR0.60 Ltr. | MAX. PRESSURE15kg/cm² |

| MODELHLH 1000-7* | DISCHARGE7cc per stroke | RESERVOIR0.70 Ltr. | MAX. PRESSURE15kg/cm² |

*Transparent reservoir

Motorized lubrication units are electric motor driven pumps along with reservoir, oil filler,

suction strainer, pressure relief valve, bleed valve etc. & are suitable for single shot

automatic Oil & Liquid Grease of Grade ‘000’ lubrication. These motorized lubrication units are

to be run intermittently.

During motor ‘ON’ period (normally 5 sec) all metering cartridges eject out required amount of

Oil & Liquid Grease at various lubrication points of the machine & during motor ‘OFF’ period

(decided by lubrication frequency min.1 minute) these metering cartridges get recharged for next

lubrication cycle. These units do not require any return line connection as metered amount of

oil is lost in normal running of the machine.

| MODEL | RESERVOIR | DISCHARGE | MOTOR RPM1500(Syn) | RELIEF VALVE | PRESSURE SWITCH | FLOAT SWITCH |

|---|---|---|---|---|---|---|

| MODELHLLS 2700* | RESERVOIR2.7 Ltrs. | DISCHARGE1 LPM | MOTOR RPM1500(Syn)0.10 KW, 220V AC, Single phase | RELIEF VALVE12kg/cm² | PRESSURE SWITCHOptional | FLOAT SWITCHOptional |

| MODELHLLS 03 | RESERVOIR3 Ltrs. | DISCHARGE1 LPM | MOTOR RPM1500(Syn)0.10 KW, 220V AC, Single phase | RELIEF VALVE15kg/cm² | PRESSURE SWITCHOptional | FLOAT SWITCHOptional |

| MODELHLLU 2700* | RESERVOIR2.7 Ltrs. | DISCHARGE1 LPM | MOTOR RPM1500(Syn)0.12 Kw, 415V AC, 4Pole, 3 phase | RELIEF VALVE15kg/cm² | PRESSURE SWITCH220V, 1Amp, 1NO+1NC Contact preset at 12kg/cm² | FLOAT SWITCH220V, 1Amp, with NO or NC contacts |

| MODELHLLU-03 | RESERVOIR3 Ltrs. | DISCHARGE1 LPM | MOTOR RPM1500(Syn)0.12 Kw, 415V AC, 4Pole, 3 phase | RELIEF VALVE15kg/cm² | PRESSURE SWITCH-do-preset at12kg/cm² | FLOAT SWITCH-do- |

| MODELHLLU-05 | RESERVOIR5 Ltrs. | DISCHARGE1 LPM | MOTOR RPM1500(Syn)0.12 Kw, 415V AC, 4Pole, 3 phase | RELIEF VALVE20kg/cm² | PRESSURE SWITCH-do-preset at15kg/cm² | FLOAT SWITCH-do- |

| MODELHLLU-08 | RESERVOIR8 Ltrs. | DISCHARGE2.5 LPM | MOTOR RPM1500(Syn)0.18 Kw, 415V AC, 4Pole, 3 phase | RELIEF VALVE25kg/cm² | PRESSURE SWITCH-do-preset at18kg/cm² | FLOAT SWITCH-do- |

| MODELHLLU-20 | RESERVOIR20 Ltrs. | DISCHARGE2.5 LPM | MOTOR RPM1500(Syn)0.18 Kw, 415V AC, 4Pole, 3 phase | RELIEF VALVE25kg/cm² | PRESSURE SWITCH-do-preset at18kg/cm² | FLOAT SWITCH-do- |

| MODELHLLU-30 | RESERVOIR30 Ltrs. | DISCHARGE2.5 LPM | MOTOR RPM1500(Syn)0.18 Kw, 415V AC, 4Pole, 3 phase | RELIEF VALVE25kg/cm² | PRESSURE SWITCH-do-preset at18kg/cm² | FLOAT SWITCH-do- |

*Transparent reservoir

Note: Model HL LS 2800* & HL LU 2800* are also available in liquid grease of grade

000.

These are piston type pump and used for automatic lubrication with the help of pneumatic pressure.It is similar to hand operated piston pumps. In this system the piston is actuated by pneumatic pressure. The recommended Input pressure in case of pneumatic system is 5-7 bars.

| Model | Details |

|---|---|

| ModelHLLS LTPn.H -600-62700 | DetailsReservoir Cap. 0.6 Ltrs. Discharge 6cc per stroke. Input Pneumatic pressure 5-7 kg/cm2. Output pressure setting 12 kg/cm2 |

| ModelLTPn .H-1700-10 | DetailsReservoir Cap. 1.7 Ltrs. Discharge 10cc per stroke. Input Pneumatic pressure 5-7 kg/cm2. Output pressure setting 15 kg/cm2 |

| ModelLTPn.H -3000-10 | DetailsReservoir Cap. 3 Ltrs. Discharge 10cc per stroke. Input Pneumatic pressure 5-7 kg/cm2. Output pressure setting 15 - 20 kg/cm2 |

HINDUSTAN LUBTRAC Rotary Pumps are geroter type pumps with positive displacement of pumps. They applicable in machines which require low discharge, medium pressure of oil. These pumps are two type : Reversible or Non – Reversible. Non – Reversible Pumps are rotates only in one direction and Reversible pumps are rotated in either directions( Clockwise & Anticlockwise).

| MODEL | DISCHARGE | MAX. PRESSURE |

|---|---|---|

| MODELHLR-1 | DISCHARGE1 Litre per minuts | MAX. PRESSURE50Kg/cm² |

| MODELHLR-3 | DISCHARGE3Litre per minuts | MAX. PRESSURE30Kg/cm² |

| MODELHLR-6 | DISCHARGE6 Litre per minuts | MAX. PRESSURE20Kg/cm² |

| MODELHLR-10 | DISCHARGE10 Litre per minuts | MAX. PRESSURE20Kg/cm² |

| MODELHLR-16 | DISCHARGE16 Litre per minuts | MAX. PRESSURE20Kg/cm² |

| MODELHLR-20 | DISCHARGE20 Litre per minuts | MAX. PRESSURE20Kg/cm² |

| MODELHLR-25 | DISCHARGE25 Litre per minuts | MAX. PRESSURE20Kg/cm² |

| MODELHLR-40 | DISCHARGE40 Litre per minuts | MAX. PRESSURE10Kg/cm² |

Note: These pump can be supplied with an electric motor also as per requirement.

Motor pump assembly is used for oil lubrication especially where continuous and high dosage of oil is required. It is also applied under oil circulation systems. It is used almost in all machines where free flow of oil is required. The different specification is available with different model. It can suck the oil from 2 ft. downwards and circulate the oil up to 10 ft. Height. The rotation of motor pump assembly is indicated on the label. Two to Three mounting holes are provided to mount the system. An electrical terminal box on the surface of the motor is provided for connection.

| Model | Details |

|---|---|

| ModelLTMPA - 1 | DetailsDischarge 1Liters per minute. Max. Pressure 15 KG/ CM2 Motor Flange Mounted with 0.25 HP , 415 AC. 1500 rpm. |

| ModelLTMPA - 3 | DetailsDischarge 3Liters per minute. Max. Pressure 15 KG/ CM2 Motor Flange Mounted with 0.25 HP , 415 AC. 1500 rpm. |

| ModelLTMPA - 6 | DetailsDischarge 6 Liters per minute. Max. Pressure 10 KG/ CM2 Motor Flange Mounted with 0.50 HP , 415 AC. 1500 rpm. |

| ModelLTMPA - 10 | DetailsDischarge 10 Liters per minute. Max. Pressure 10 KG/ CM2 Motor Flange Mounted with 0.50 HP , 415 AC. 1500 rpm. |

These are valve which eject metered amount of oil to the each lubrication point. It requires recharging time of minimum 1 minute between two cycles. An individual oil distributor is required for individual lubrication point. In order to ensure that correct amount of lubrication point, oil distributor of correct dosage should be selected. These are available in both MS & Brass material for Oil & Liquid Grease Grade ‘000’ media.

| Model | Details |

|---|---|

| ModelLTD-1 | DetailsDosage 0.01cc, 0.03 cc, 0.05 cc, 0.10 cc, 0.16 cc per stroke. |

| ModelLTD-2 | DetailsDosage 0.25 cc, 0.40 cc per stroke. |

| ModelLTD-3 | DetailsDosage 1.0 cc, 1.60 cc per stroke |

Note:We are manufacturing injectors in both BRASS and M.S. Metering Cartridges are also available in liquid grease of grade 000.

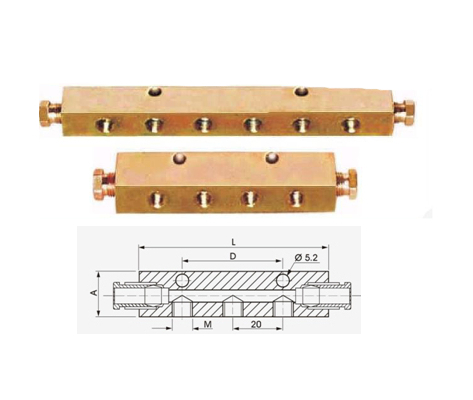

Manifold are required for mounting of oil distributers. These are having two ports of 6mm OD tube and few side outlets. Oil distributors are screwed directly on side outlets of manifolds.

| MODEL | L mm | A mm | Thickness mm | M mm | D mm | Mounting Holes |

|---|---|---|---|---|---|---|

| MODELM-1 | L mm35 | A mm18 | Thickness mm15 | M mmM8X1 | D mm- | Mounting Holes1 |

| MODELM-2 | L mm55 | A mm18 | Thickness mm15 | M mmM8X1 | D mm- | Mounting Holes1 |

| MODELM-3 | L mm75 | A mm18 | Thickness mm15 | M mmM8X1 | D mm40 | Mounting Holes2 |

| MODELM-4 | L mm90 | A mm18 | Thickness mm15 | M mmM8X1 | D mm40 | Mounting Holes2 |

| MODELM-5 | L mm115 | A mm18 | Thickness mm15 | M mmM8X1 | D mm40 | Mounting Holes2 |

| MODELM-6 | L mm135 | A mm18 | Thickness mm15 | M mmM8X1 | D mm60 | Mounting Holes2 |

| MODELM-7 | L mm155 | A mm18 | Thickness mm15 | M mmM8X1 | D mm60 | Mounting Holes2 |

| MODELM-8 | L mm175 | A mm18 | Thickness mm15 | M mmM8X1 | D mm40 | Mounting Holes2 |

| MODELM-1A | L mm40 | A mm22 | Thickness mm22 | M mmM10X1 | D mm- | Mounting Holes1 |

| MODELM-2A | L mm65 | A mm22 | Thickness mm22 | M mmM10X1 | D mm- | Mounting Holes1 |

| MODELM-3A | L mm90 | A mm22 | Thickness mm22 | M mmM10X1 | D mm50 | Mounting Holes2 |

| MODELM-4A | L mm115 | A mm22 | Thickness mm22 | M mmM10X1 | D mm50 | Mounting Holes2 |

Mist. Lubrication System which is best suited for coneyor, Machine tools spindle,

Chain, Sponge iron plant & Cement plant. bearing etc.

In Mist Lubrication System used the pump for carrying the oil up to atomizer. In

atomizer two port is provided one for oil another for air This pump is pneumatically

operated as well as motorised.

Pneumatic pump is suitable for intermittent lubrication. we can get continuous

lubrication also. In this pump an acrylic / metalic reservoir with a capacity 2Ltr. / 5

Ltr., Discharge (Adjustable) Input air Pressure 3 to 5 kg/cm² (accordingly

customers requirment also.) and oil filling port is provided on the top. Through air

pressure. Oil come in junction block (atomizer) Motorised pump is suitable for

continuous / intermittent and muilti point lubrication. Through motorised pump

lubrication come in atomizer with the help of progressive block/metering

cartridge/control valve from the atomizer we get the mist lubrication.

| Model | Details |

|---|---|

| ModelHLOML-2/PS/FS | Details2 Ltr. |

| ModelHLOML-5/PS/FS | Details5 Ltr. |